Safe, fast-charging, long-life Li-ion batteries with the Echion XNO® anode materials

→ SAFER → FASTER → LONGER

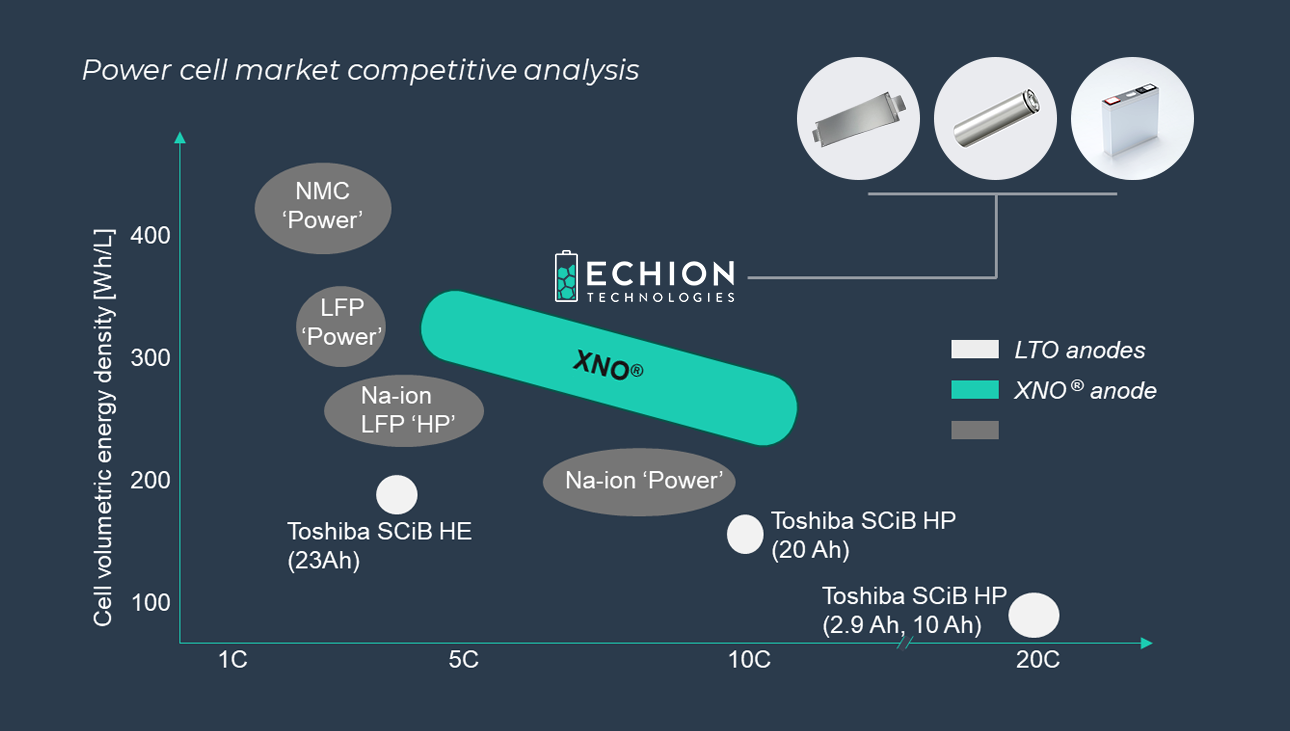

Lithium-ion batteries designed with Echion XNO® anode materials achieve a unique combination of high safety, extreme fast-charge and discharge capability, and very long cycle-life. We achieve this together with up to double (x2) the energy density of market leading LTO cells.

This unique performance envelope is ideal for high-power batteries electrifying heavy-duty commercial and industrial applications, a premium, fast-growing market driven by total cost of ownership.

Our XNO® materials are based on proprietary mixed niobium oxide compositions and microparticle designs protected by multiple international patent families, 6 of which have granted patents.

Fast-track your cell development with XNO®

XNO® materials are moisture-stable, micrometric particles, which have gained a reputation for being extremely easy to handle and process under industrial mixing and coating conditions.

We have optimised our materials to work equally well with NMP, aqueous, and dry extrusion processes. XNO® is compatible with standard current collectors (aluminium and copper), binders, separators, electrolytes, and cathodes. XNO® has been demonstrated in commercial batteries.

Our team of customer success experts can support cell manufacturers with advice on electrode formulations, cell designs with various loadings, cathodes, testing protocols, cell ageing, and general cell development troubleshooting.

A more sustainable

battery with XNO®

Independent research has found that XNO® has a lower environmental impact when compared to lithium titanate (LTO) anodes when evaluated at a material and cell level. A study by Ghent University, which has been peer-reviewed in the Sustainable Materials and Technologies Journal, found a 51% difference in global warming potential (GWP) in supply of the two anode materials, in favour of XNO®. You can read more here.

XNO®’s ability to deliver a superior environmental performance than commercial lithium-ion and graphite battery anode materials further adds to the distinctive performance attributes of our material. This has proved to be of great interest to OEMs and cell manufacturers who are searching for solutions that will meet greater carbon neutrality demands in response to legislative, social and environmental pressures.

Request XNO® materials

Our 3rd generation XNO® anode material is available world-wide today. The opening of our 2000 t/year production plant in 2024 means it can be supplied at scale.

We typically supply samples up to 1 tonne scale under a simple Material Transfer Agreement, and have the ability to enter multi-year supply agreements for larger quantities guaranteeing outstanding quality, support, and supply security to our customers.

The XNO® Supply Chain

UK-based R&D and pilot plant

Scaled to 2,000 t/y XNO® toll manufacturing facility in Brazil

Equivalent to ~1 GWh of Li-ion cells

Supplying globally and minimising transport from primary material source

Public Environmental Product Disclosure (EPD) showcasing reduced impact vs graphite, LTO

A network of cell manufacturers, pack makers and engineering integrators, all working with XNO® to bring your electrification commitments to completion